Seam Tracking Overview

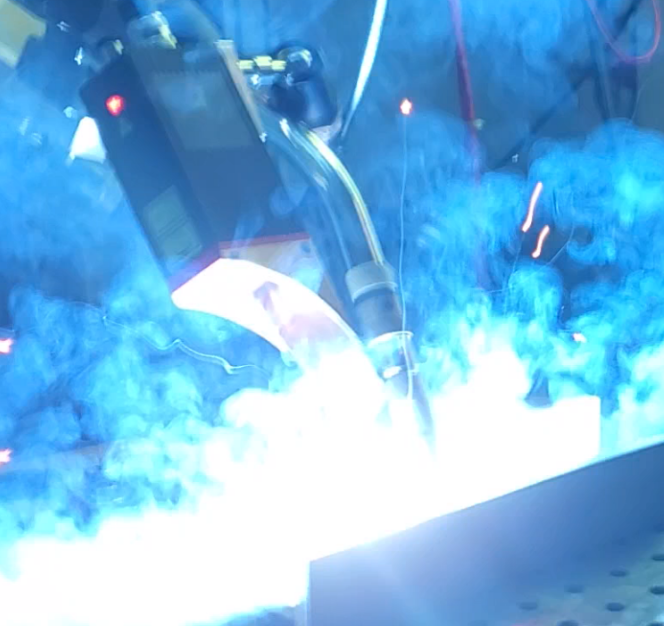

With the application of laser technology, many production tasks can have more intelligent and more accurate solutions, which cannot be solved by traditional methods. ScoutVision optical tracking system was developed for such applications and has met many production requirements since its launch.

The ScoutVision system is able to position the robot in three dimensions along the weld with an accuracy of ±0.1 mm, while the direction of the processing head relative to the workpiece surface remains constant according to the preset value.

The programming of the robot path is a time-consuming process and has to be made after machining and after each modification of the workpiece. But this process can then be eliminated and simplified by just defining a few points. These points include the starting point of the seam within the search area, as well as a few points for possible changes of welding parameters along the path.

Real time image processing allows high tracking speed to automate all fast machining processes such as welding, cutting, gluing, sealing, accurately tracking the 3D-path.

ScoutVision system is able to adapt to the maximum possible tracking speed, such as a small bend in the path that will result in a high horizontal acceleration.